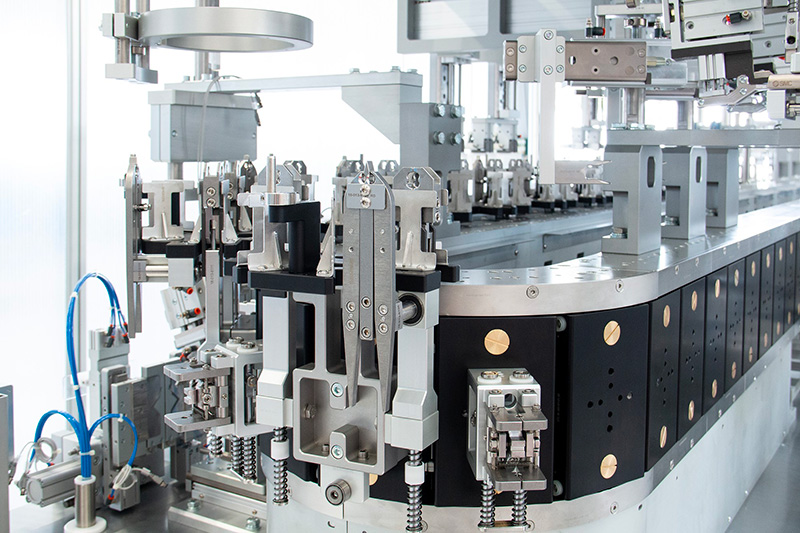

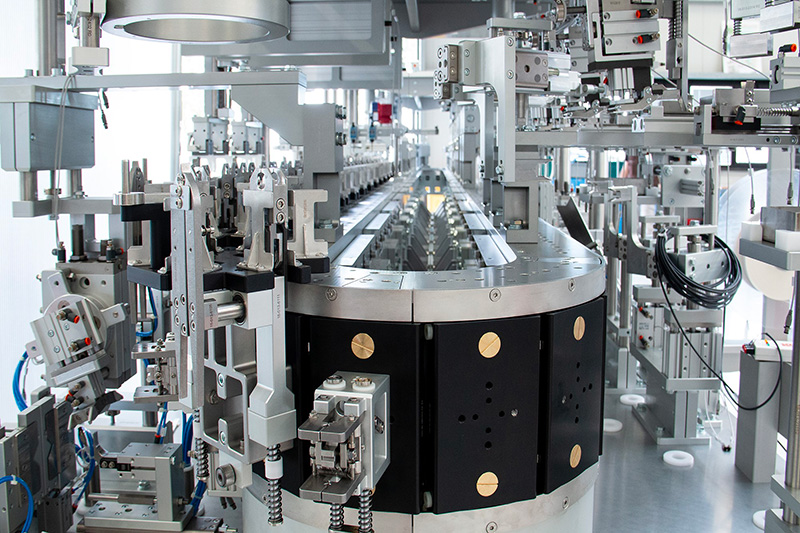

MOTION SYSTEM FOR ASSEMBLY TECHNOLOGY

Free Pallet Motion System is A UNO TEC own design modular equipment characterized by an independent, flexible and settable movement, based on ILSM - Independent Linear Sinchronous Motors - designed and manufactured by Motor Power Company.

A UNO TEC realizes and installs this revolutionary technology on its own automatic assembly machines, providing its Customers with unprecedented benefits compared to any traditional motion system.

Main Benefits:

- Customizable length and shape

- Rise in productivity without affecting machine footprint

- Process flow optimization

- Maximization of efficiency in productivity

- Flexibility for future implementations on the machine

- Cost cutting thanks to working units reduction

- Settable acceleration and deceleration rates, ideal for fragile products

- Customizable motion speed

- Fast change of setup

- Easy-low maintenance, compared to traditional mechanical transfer

- Compatibility with every PLC

Technical characteristics:

- Curve radius: 212 mm

- Module length: 500 mm

- Pallet length: 120 mm

- Payload: 15 Kg

- Maximum acceleration: 15 m/s²

- Maximum speed: 2 m/s (with max load)

- Maximum deceleration: 15 m/s²

- Accuracy < 0,1 mm

- Repeatability < 0,5 mm

- Feedback: absolute magnetic encoder

- Integrated RFID technology in any position

- STO SIL3

- 230VAC three phases

- 1,6 A + (1,2 A each linear meter)

More features:

- Free mobility for one or more carriers;

- Absolute carriers positioning;

- Arbitrary system length and carriers number;

- Individual and synchronized carriers movement;

- Integrated collision avoidance sensor;

- Acceleration/deceleration, positioning and constant force over the entire conveyor system;

- Material transport and processing on curves;

- No moving cables.

To receive the complete video, send us your data by filling out the form below