- Home

- News & Press

- TUBING COILING AS FIRST STEP IN A SEMIAUTOMATIC ASSEMBLY PROCESS

TUBING COILING AS FIRST STEP IN A SEMIAUTOMATIC ASSEMBLY PROCESS

27-05-2021

Medical disposables assembly process can be manual, semiautomatic or fully automatic. The choice of the most suitable assembly strategy depends from the type of product to assemble and, even more, from the productive volume, which can justify or not the return on investment following the automation purchase.

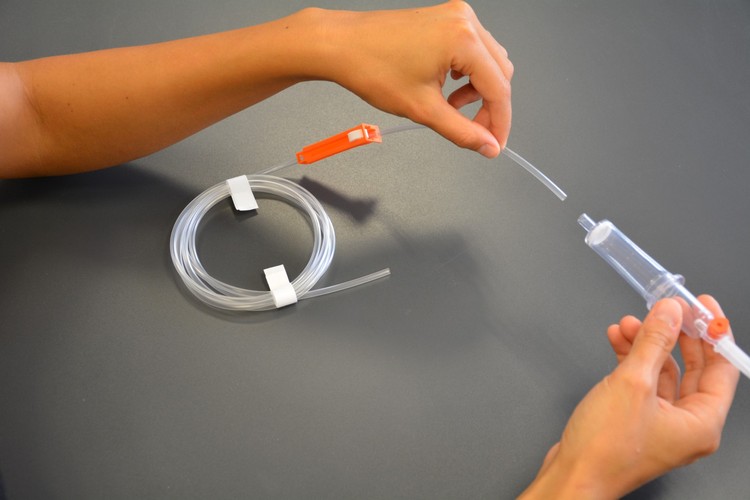

How to speed up and improve the quality of a manual assembly process, avoiding the financial commitment that a complete automation would imply? The production of a semi-finished tubing set represents a semi-automatic process starting from the machine to the operator.

Small coils are convenient when moved and handled in clean room for any process, including packaging purpose.

Moreover, cohesive tape wrapping is easy and safe to be removed whenever required.

A UNO TEC solution is BANDY System, a flexible-modular solution based on 4 main working units operating in sequence.

BANDYCCB is highly indicated to improve productivity and quality of sub-assemblies which are part of infusion sets, heparin and extension lines, etc.

Tubing length, coil diameter, free tubing ends length, tape position and coil configuration can be programmed and adjusted.

BANDYCCB MAXI can process tubing of different elastomers with external diameter up to 10.0 mm and fasten coils with 1/2” (13 mm) or 1” (25 mm) width medical grade cohesive tape (with Latex or Latex-free).

For small tubing and coils please also check smart-compact BANDYCCB Mini.

Once the semi-finished product has been made, i.e. a coiled and banded tubing, the gluing process of components aimed to obtain a finished product, whether it is an infusion set rather than a heparin line, can be easily completed manually by the operator.

Medical tubing coiling and banding operations, together with the strategies on the type of assembly to be adopted, are delicate and essential to guarantee a high-quality finished product without risks. It is therefore necessary to choose a reliable system suitable for your specific tubing (material, dimensions, length), as well as for your production needs.

If you are looking for the right partner to choose the automatic machine suitable for your product, contact us now.

A UNO TEC is a consulting, design and manufacturing company specializing in customized automatic machines created on YOUR specific needs.

IF THE SOLUTION DOESN'T EXIST, WE WILL CREATE IT FOR YOU!

Find more here: https://www.a1tec.it/automatic-production-machines...

Or attend next A UNO TEC Virtual Event taking place on June 7-8. Book your space now: https://www.aunotec.it/en-gb/exhibitions